Picking location determination for STO

Manually

determining picking locations for every outbound delivery in SAP can be a

tedious and error-prone process, especially in fast-paced warehouse

environments. Fortunately, SAP offers various configurations and functionalities

to automate this process, allowing for a more efficient and streamlined

warehouse workflow.

This blog post

will guide us through the key concepts and configuration steps to achieve

automatic picking location determination in the SAP system.

Understanding the

Fundamentals

Before diving

into configurations, let's clarify some core SAP concepts related to picking

location determination:

Ø

Picking Location: This

is the physical location in the warehouse where the stock is stored and from

where the picker retrieves the materials for an outbound delivery.

Ø

Shipping Point: This

organizational unit represents the point from which outbound deliveries are

shipped to the customer.

Ø

Plant: A

plant in SAP represents a physical location where materials are manufactured,

stored, or distributed.

Ø

Storage Location: A

storage location is an organizational unit that subdivides a plant according to

the purpose of the storage space (e.g., raw materials, finished goods).

Whenever we create the deliveries for STO, we will see that the storage location is missing for the items if the picking location is not determined automatically.

In order to perform picking and goods issue we need to enter the

storage location manually for each item in the delivery.

To avoid the manual entry of storage location for each item in

delivery we can configure the system to determine it automatically.

Configuration settings required:

Step1: Define the rules for picking location determination.

IMG-> Logistics execution-> Shipping-> Picking->

Determine picking location-> Define the rules for picking location

determination.

In this step, you assign the rule to determine the storage location to delivery type.

Step2: Define storage conditions:

IMG-> Logistics execution-> Shipping-> Picking->

Determine picking location-> Define storage conditions

In this step, you define the shipping conditions which are used in

the rule to determine the storage location.

Step3: Assign picking locations

IMG-> Logistics execution-> Shipping-> Picking->

Determine picking location-> Assign picking locations

In this step, you assign the storage location which should be

populated in the delivery item for the rule conditions (combination of shipping

point/plant/storage condition).

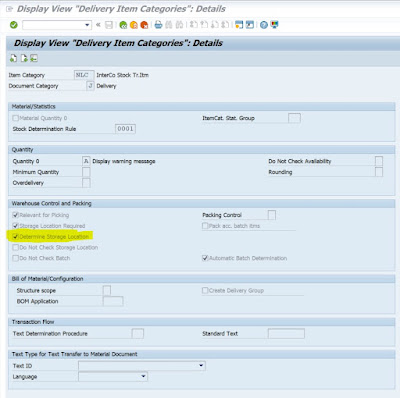

Step4: Defining the automatic determination of storage location for delivery item category

IMG-> Logistics execution-> Shipping-> Deliveries->

Define item categories for deliveries

Master data setting:

We need to assign the storage conditions for the material in plant

data/stor. 1 view

Benefits of

Automatic Picking Location Determination

Ø

Increased

Efficiency: Significantly reduces manual effort and processing time for

outbound deliveries.

Ø

Reduced Errors: Eliminates

the risk of human errors associated with manual picking location assignments.

Ø

Improved

Inventory Accuracy: Real-time updates and tracking of stock movements

within the warehouse.

Ø

Optimized Picking

Routes: Can be integrated with WM/EWM to optimize picking paths,

minimizing travel time for warehouse staff.

Conclusion:

By implementing automatic picking location determination in SAP, we can streamline our warehouse processes, improve efficiency, and enhance inventory accuracy. This blog provided an overview of various methods and steps involved. Remember to tailor the implementation to our unique business requirements and leverage the power of SAP to optimize our warehouse operations.

#Pick Point Determination #Delivery Processing #Shipping Point Determination

#Storage Location Determination

No comments:

Post a Comment